Electrics/Electronics

Automation used in the electrical and electronics industries is associated with particularly high requirements on flexibility, product diversity, short cycle times and a variety of technological challenges. We meet these requirements with modular assembly systems. The modular design allows the modification of automation degree according to particular tasks from clients. In this way, the systems can be effectively adapted to technological changes.

Production cells

Clinch automation

Technologies

Handling, pallet transport, clinching

Structure / Specialties

Intereface to injection molding machine: Fanuc robot, pallet circulation system, integrated rotary indexing table, 2 servo-electrical presses

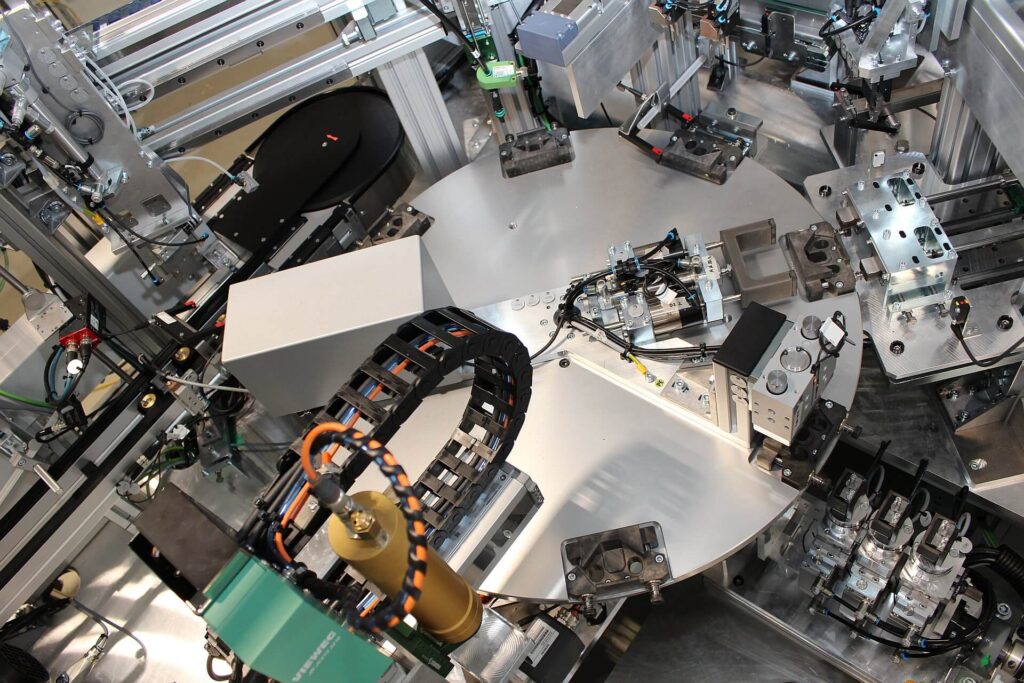

Automatic assembly systems

Automatic assembly machine for plug

Technologies / Structure / Specialties

Quick change of adapters, pneumatic handling, integrated EOL control, rotary indexing table: compact design, parts feeding from bulk material, assembly control: camera station

Automatic assembly machine for sensor

Technologies

automatic screwing, pressing of contact pins, joining with force-stroke monitor, camera control, dosing of grouts

Structure / Specialties

parts feeding from, tray palletizer, coupling serial number with database, automatic packaging

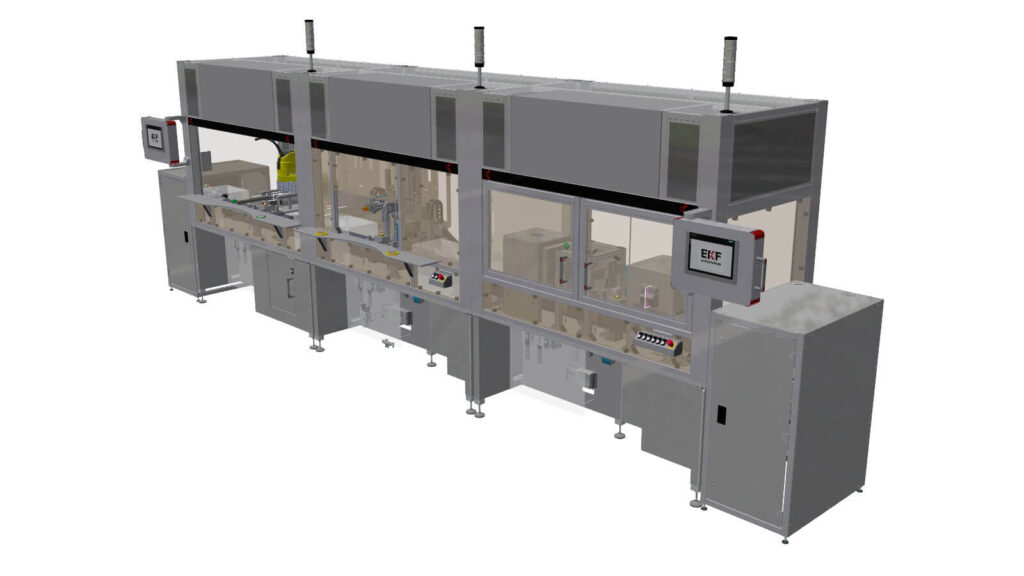

Modular assembly systems

Final assembly line for sensor

Technologies

Parts feeding from bulk, unwinding/cutting/bending of flat-top screen, force-stroke monitored assembly, assembly of printed circuit boards, assembly and casting lids, integration of solder joint inspection

Structure / Specialties

Combination of manual workstations with automatic stations, product data management and data handling for tracking, integration of a soldering unit

Modular assembly line for plug

Technologies

automatic infeed and outfeed of tray from tray stacks, parts handling by Scara robot, seal assembly, electrical and optical tests

Structure / Specialties

modular station design – conversion from manual to automatic stations is possible