Automotive

We are a long-term partner and supplier of the automotive industry. Our automation solutions for assembly and production are used in the manufacture of exterior and interior components as well as for powertrain assemblies and for the production of individual parts.

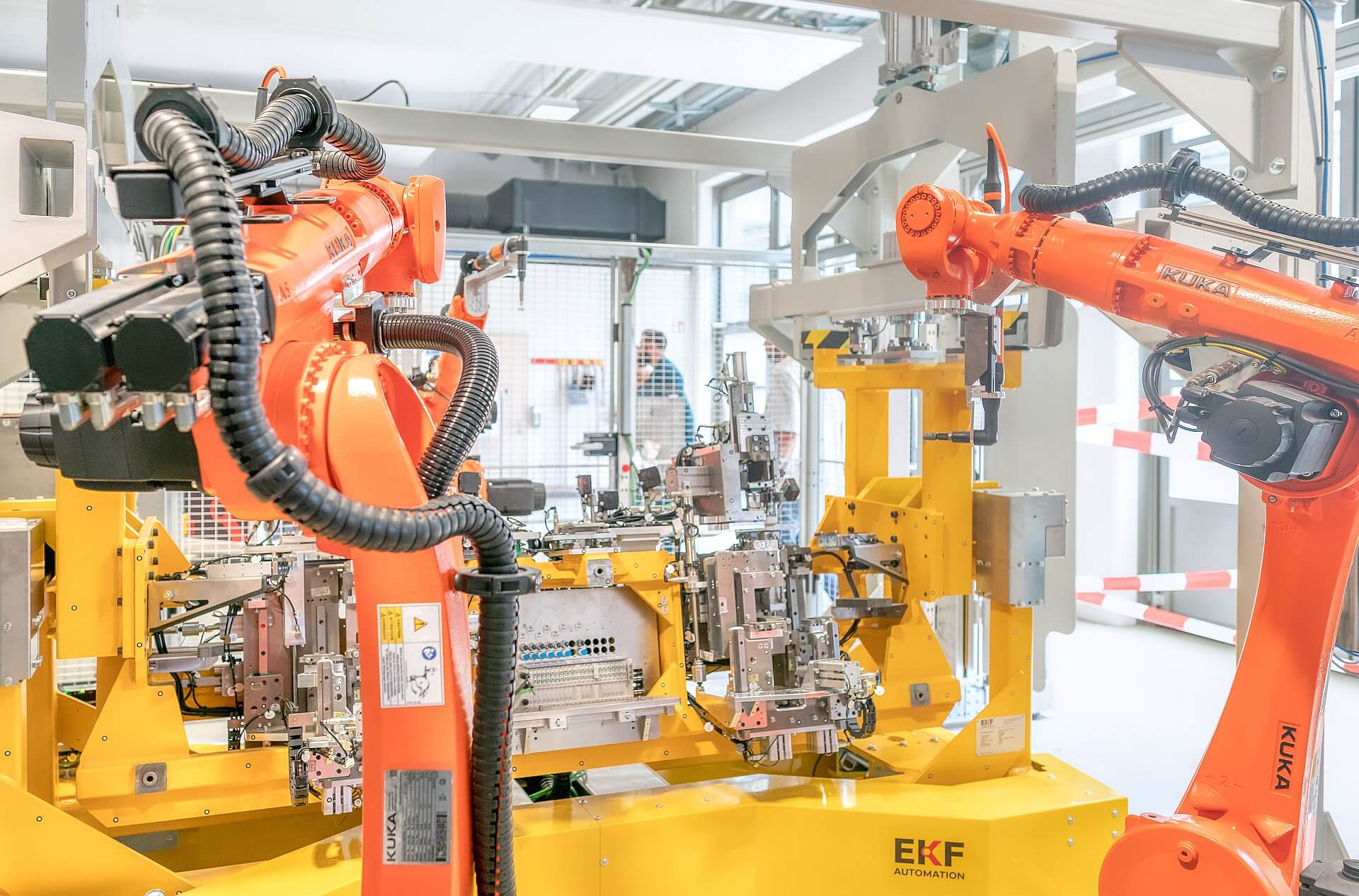

Production cells / Production lines

Palletiser for pistons

Structure / Specialties

Integration of a measuring station, interlinking of the cell with a grinding machine

Assembly vehicle components interior/exterior

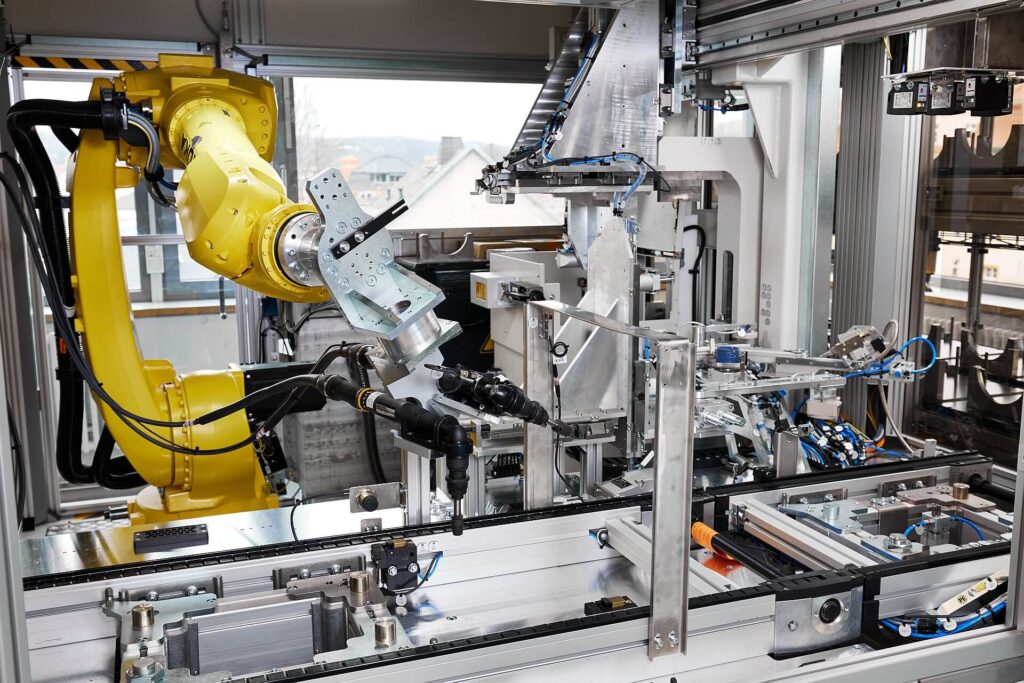

Semi-automated assembly devices

challenging topics

high technological density in a small space, adjustability in the smallest installation space in miniature format

Technologies

automatic infeed of screw driver, pneumatic balancer for manual device to support human-machine interaction, communication with superordinate assembly protection system, standardized shim assemblies

Structure / Specialties

semi-automatic assembly of various plastic injection-molded and aluminum castings into a complete assembly, use of poka-yoke strategies to avoid assembly errors, automatic recognition of the components in the devices, Execution of the control system in step or automatic sequences, operator-guided assembly with complete traceability

Assembly line for vehicle modules

Technologies / Structure / Specialties

automated screwing of individual components, Integration of an driverless transport system DTS, safeguarding of the entrance and exit area of the DTS by contact-free protective devices, automatic loading and discharge of the finished modules, connection to a superordinate control system to ensure the assembly quality

Modular assembly systems

Modular assembly line

Technologies

Dosing of lubricants, adhesives and sealants, force- stroke monitored pressing of various components, manual and fully automated DC screwing, optical inspection for quality monitoring, DMC marking by laser, leakage test, function test

Structure / Specialties

modular station structure and combination of manual and fully automatic processes, operator-controlled assembly, Master computer including database

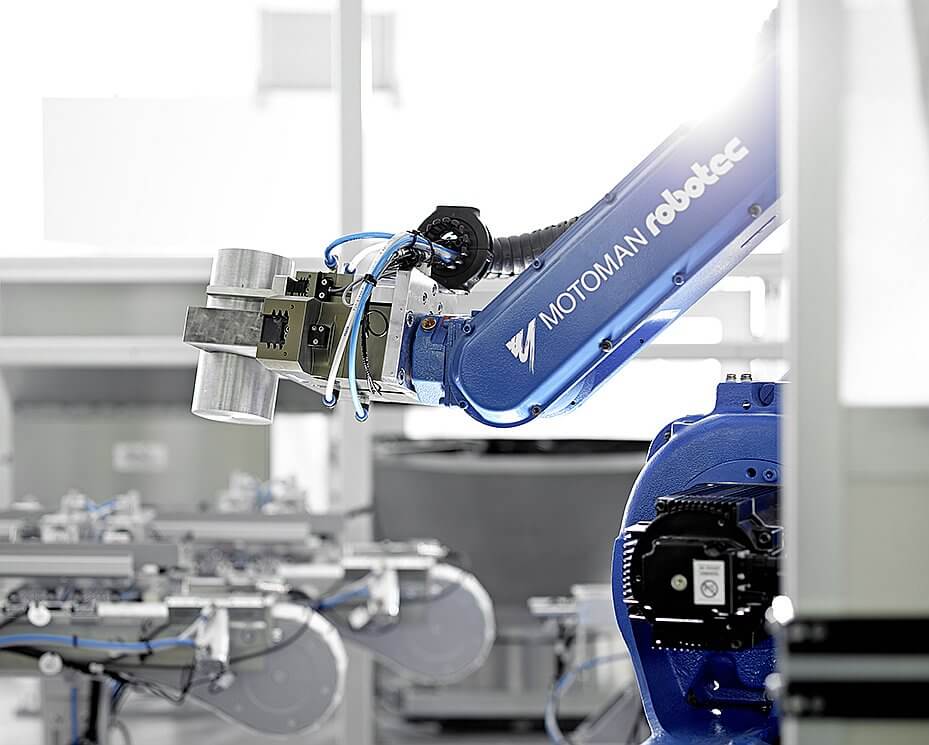

Packaging machines

Automated testing and packaging machine

Technologies

extensive final inspection by means of integrated image processing

Structure / Specialties

2 camera inspection stations, 3 KUKA robots, Timing and buffering belts, Siemens PLC and measuring computer

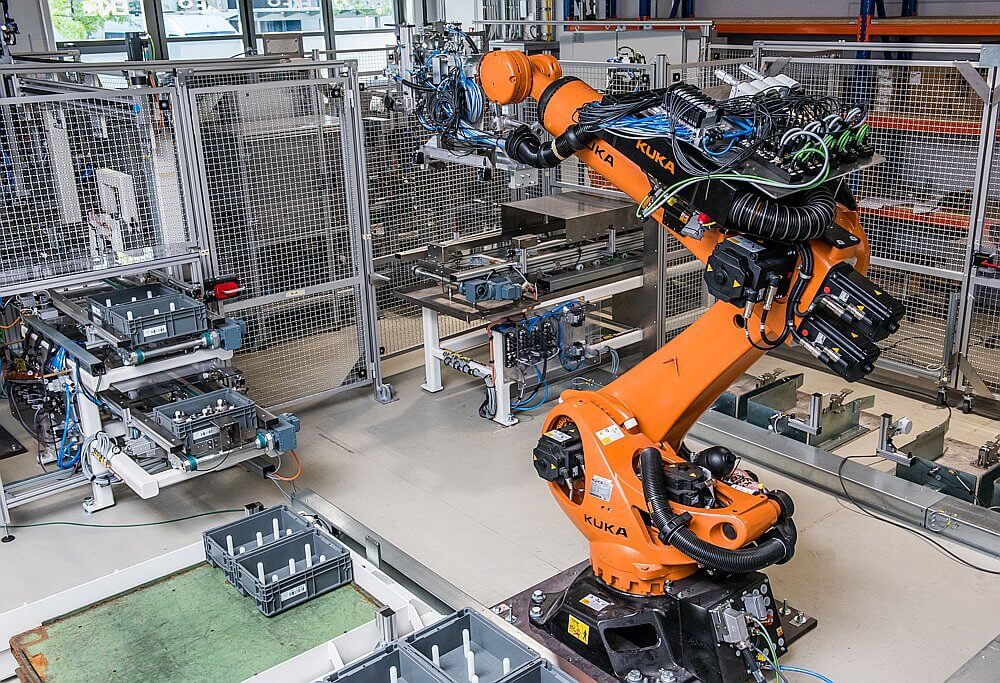

Robot cells

Protective ring assembling

Technologies

force-stroke monitored joining

Structure / Specialties

Parts feeding via conveyor belts, parts handling by robots, universal gripper

Automatic assembly machine with palletizing robot

Technologies

Assembly parts unraveling, separating and feeding in the correct position, camera inspections, finished parts palletizing, storage table for different feeding systems (fast set-up), Palletizing by FlexPicker, tray handling for raw and finished part pallets

Robot cell

Technologies / Specialties

4 interchangeable gripping systems, automatic set-up, stacking cell with 3 stacks, niO drawer, KUKA robot